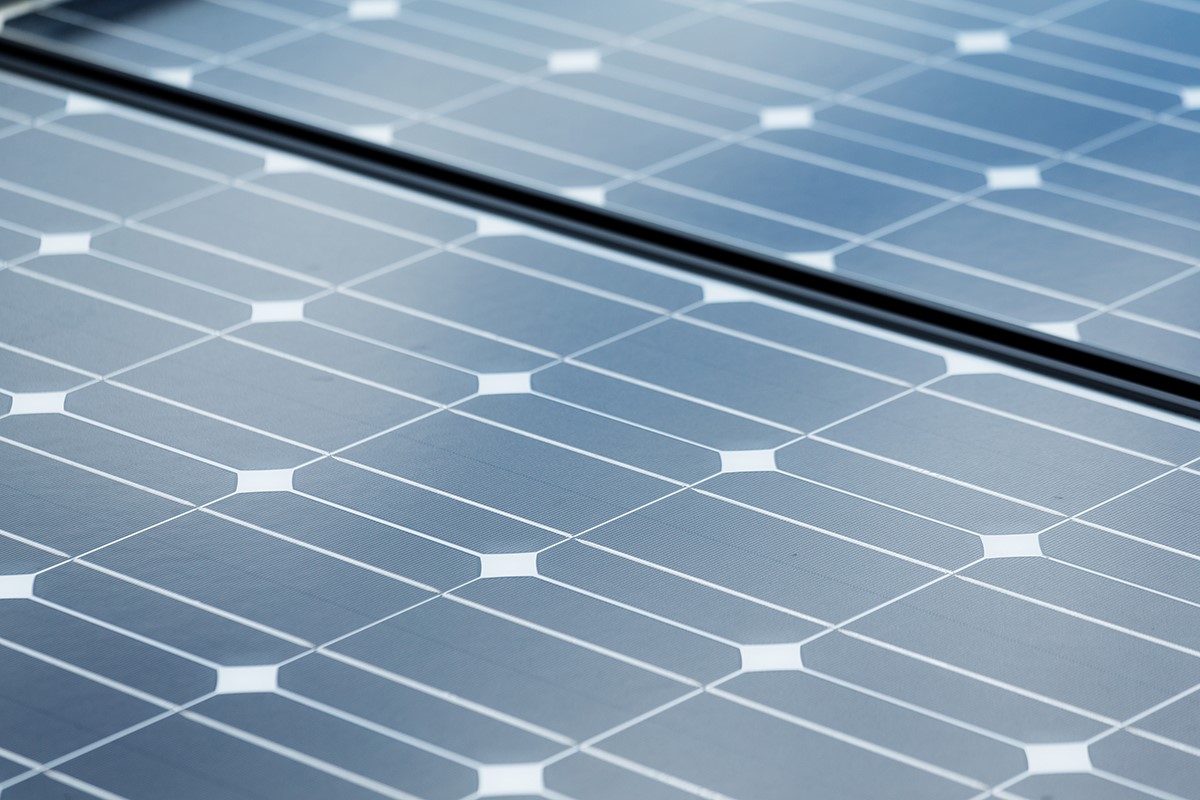

The creation of a solar panel is truly captivating; it melds scientific precision with sustainable ingenuity. Witnessing the transformation of humble silicon ingots into powerful energy-generating units is like observing a symphony of technology and nature.

As each layer is meticulously crafted, a sense of wonder arises as these panels will soon capture and convert sunlight into electricity for Sacramento homeowners and businesses. This process, a harmonious blend of innovation and environmental mindfulness, stands as a testament to human innovation’s capability to harness the boundless energy of the sun and illuminate a path toward a more sustainable future with renewable energy.

Here’s a step-by-step overview of what solar panel manufacturing entails.

Silicon Ingot Production

The main material used in solar panels is pure silicon. The manufacturing process starts with the creation of silicon ingots. High-purity silicon crystals are melted and then solidified into large cylindrical ingots.

Wafer Slicing

The silicon ingots are sliced into wafers. A wafer is a thin layer that’s typically around 150-200 micrometers thick.

Wafer Surface Treatment

The wafers undergo surface treatment processes to remove any impurities or saw damage. This might involve etching, texturing, or cleaning to improve light absorption.

Doping

Doping involves introducing specific impurities into the silicon wafers to create a positive and a negative layer, forming a P-N junction. Phosphorus is often used for the N-type layer, and boron for the P-type layer.

Anti-Reflective Coating

A thin anti-reflective coating is administered to the front surface of the solar cell, aiming to reduce sunlight reflection and amplify light absorption.

Metalization (Front and Back Contacts)

Metal contacts are affixed to the front and back of the solar cell. Silver or another conductive material is screen-printed onto the front and back surfaces to allow for the collection and flow of electricity.

Firing

The photovoltaic cell goes through a high-temperature firing process. This fuses the metal contacts with the silicon surface, ensuring good electrical conductivity.

Testing and Sorting

Each individual cell is tested for efficiency and quality. They are sorted by their performance results.

Cell Interconnection

Photovoltaic cells are interconnected to form a larger unit called a solar module or panel. Conductive wires or ribbons are soldered or laminated to connect the cells in series or parallel configurations.

Encapsulation

The interconnected solar cells are encased within a shielding material, frequently EVA (ethylene vinyl acetate), between a front glass cover and a back sheet. This encapsulation protects the cells from environmental factors and provides electrical insulation.

Frame Installation

The encapsulated solar cells are placed within a frame made of aluminum or another durable material. This frame provides structural support and protection for the module.

Testing and Quality Assurance

The fully assembled solar panel undergoes a series of tests to ensure it meets performance and safety standards. These tests include electrical performance, insulation and durability tests.

Packaging and Shipping

Once the solar panel passes all tests, the solar panel manufacturing process is finished. The solar panels made are packaged and prepared for shipping to distributors, installers, or customers.

Installation and Connection

Solar panels are installed on rooftops, ground mounts, or other suitable locations. They are wired together to form solar arrays. The solar power generated can be used directly or supplied to the grid.

It’s worth noting that different manufacturers in the solar industry might have variations in their processes, solar cell technology and solar panel materials, but these are the fundamental steps involved in solar panel production.

Go solar with your trusted Sacramento solar company

Sacramento homeowners seeking to harness the transformative power of solar energy can confidently turn to Aztec Solar as their premier choice.

With over four decades of experience in the solar industry, we stand as a beacon of excellence in solar solutions. From meticulous design to flawless installation, we’re dedicated to helping you maximize energy savings and minimize environmental impact. Contact us today for more information.

Recent Comments